|

|

|

updated 7 October 2014 |

||||

|

|

||||

|

This site presents the results of experiments I am doing on how smoothing planes can be brought to their highest level of performance. -- Steve Elliott The issues that interest me are:

I have a related site that describes my efforts to compare the various types of steel that are used in plane blades. The link below will take you there. |

||||

|

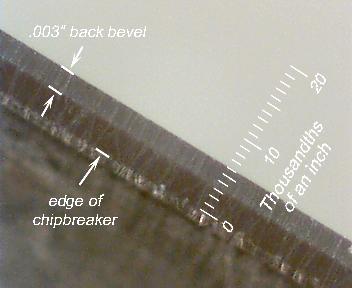

Chipbreaker Distance and Edge Shape I use a small microscope to measure the distance between the chipbreaker edge and the cutting edge of the blade. Here’s a sample image at 200 power:

The chipbreaker edge is set at a distance of .006” from the cutting edge of the blade. After only a little practice I have been able to set the chipbreaker within +/- .001” using nothing more than a strong pair of reading glasses. It’s not necessary to have a microscope to adjust a chipbreaker accurately. In the image above, the light-colored band .001” wide just behind the chipbreaker edge is a microbevel at 75º that the shaving hits as it slides up the blade. Viewed end-on, this microbevel is about .005” wide.

Mouth Dimension A narrow mouth greatly improves the surface produced when planing against the grain. Smoothing planes can work well when the width of the mouth is as small as a few thousandths of an inch. Achieving this fine a mouth involves careful tuning of both the blade and the plane body.

In the scan above, the mouth dimension is .008 inches. I believe a mouth only half this size would be better for a dedicated smoothing plane.

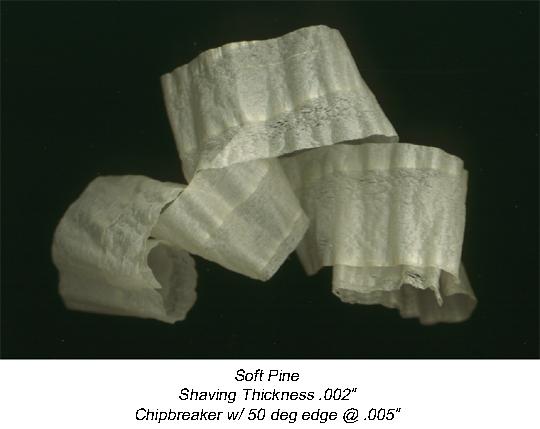

Shaving Characteristics To examine and record the shavings produced, I scan them on a flatbed scanner. Here’s a sample shaving:

This scan shows both the overall shape of the shaving and the state of the wood. In this case the shaving is curly, slightly rippled, and shows no breaking of the wood fibers. This is known as a Type II shaving, which is typical of thin shavings made by smoothing planes with standard bed angles. For the system used to classify shavings, see the page Shaving Formation.

Shaving Formation Both the surface of the wood being planed and the shaving produced are affected by what happens to the wood as it is being cut. Sometimes the wood splits and breaks, other times it bends without breaking. Close attention to the shaving that has been cut can give a good idea of what type of cutting action is taking place. Here is a diagram of the cutting action that I believe is typical of smooth planing when using a plane with a bed angle between 45 and 50 degrees:

This is called a Type II chip (or shaving). It is the type of cutting that produces a curly shaving that is not broken into segments, as often happens when a thicker shaving is cut.

|

|

[Home] [Summary of Results] [Testing Procedure] [Chipbreaking] [Cutting Angles] [Shaving Formation] [Tuning Infill Planes] [Links & References] [Contact] [Site Map] |