|

|

|

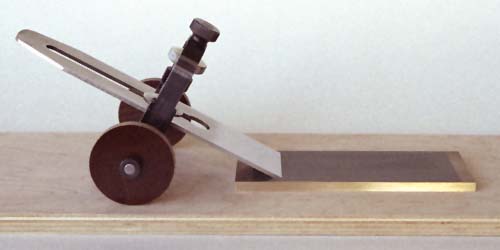

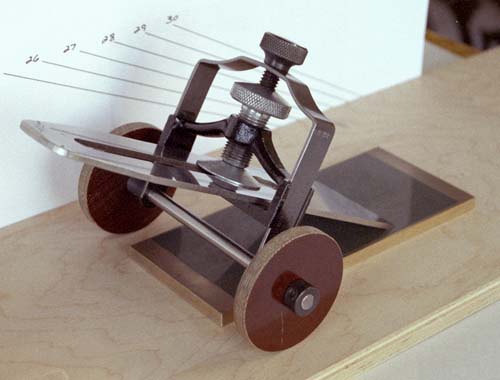

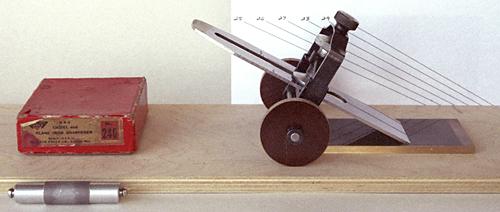

Each blade is ground to a 25º primary bevel using a Tormek low-speed wet grinder to avoid any chance of burning the edge. The bevel is honed using diamond paste on a cast iron plate. Sometimes an intermediate abrasive is used at about 2º above the grind angle, and the diamond paste is used at 2º above that. In most cases the blades are sharpened with a back bevel of 2½ º. The results are recorded as if the plane had a bed angle equivalent to its true bed angle plus the angle of the back bevel. So far all of the planing has been done using planes with 45º beds. Note: In the years since I wrote these pages Iíve developed my own honing jig which can be seen here. Iím leaving the description below on this site in case it might be helpful to those who would rather adapt a jig that can be purchased used than fabricate their own jig. To make sure the bevel angle is precise I use a modified Millers Falls #240 honing jig. The modification Iíve made is to remove the roller and replace it with an axle and wheels that donít ride on the stone. This allows me to make strokes along the entire length of the stone. Here are some pictures of my first version of this modification:

The black knob on the top of the jig adjusts the bevel angle within a range of about nine degrees, depending on blade extension. Since I took these pictures Iíve done an extensive new version of this setup. It now includes a holder for stones that rocks back and forth so that the blade edge always touches the stone across the bladeís entire width. This makes setting the jig much quicker. The new version also includes a provision for honing back bevels. It allows me to alternate between honing the main bevel and the back of the blade, which is how Iíve had the most success in removing all of the wire edge. Details of the new version are available on my site Comparison Tests of Plane Blades. After considerable experience honing and examining blades of different types, Iíve become convinced that a more finely honed edge is usually achieved through use of a back bevel. Iíve been a professional cabinetmaker for 30 years and had never used back bevels until I started this study, preferring to lap the entire back of the cutting portion of the blade. After examining and testing many blades that I thought would be sharp and finding scratches or a wire edge, I now prefer a carefully honed, very narrow back bevel.

|

|

[Home] [Summary of Results] [Testing Procedure] [Sharpening] [Planing] [Chipbreaking] [Cutting Angles] [Shaving Formation] [Tuning Infill Planes] [Links & References] [Contact] [Site Map] |