|

|

|

Mechanics of chipbreakers and high cutting angles in woodworking handplanes. Kees van der Heiden, The Netherlands, 2014.

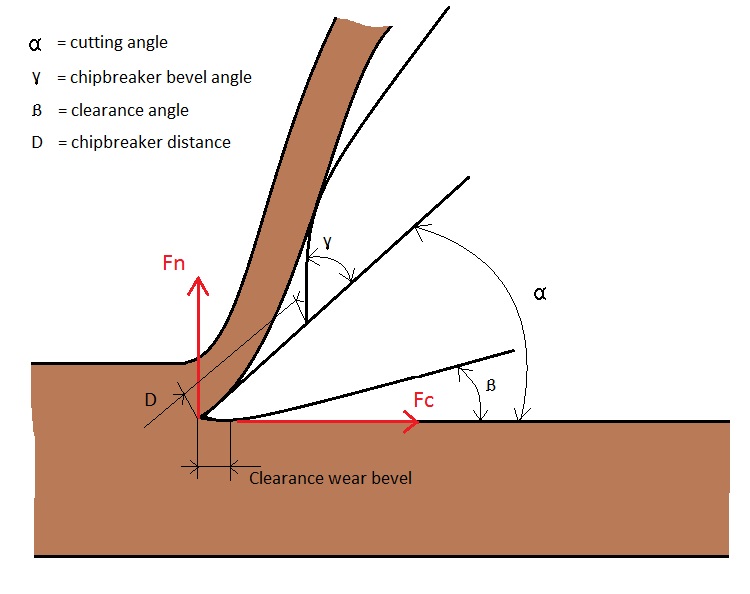

Abstract When using handplanes, tearout is a typical problem. Two methods to prevent tearout are high cutting angles and chipbreakers set very close to the cutting edge. In previous work it was found that a cutting angle of 60° is equivalent to a chipbreaker setting of 0.1 mm behind the edge when the chipbreaker edge is beveled at 45°. Likewise an angle of 55° is equal to a 0.2 mm setting of the chipbreaker. To compare the two methods a planing machine is used with force transducers to measure the cutting force Fc and the force perpendicular to the wood surface, the normal force Fn. Fc proved to be 30% higher for the plane setups with a high cutting angle, compared to the equivalent chipbreaker settings. Fn is normally negative, pulling the edge into the wood in a standard 45° plane without the chipbreaker. When setting the chipbreaker close to the edge this negative force is slightly reduced, but in high angle planes this is reduced much more and tends towards 0 around a 60° cutting angle, under the circumstances of this experiment. A second experiment has been conducted to measure the forces after a planing distance of 100 meters. The rate of change of Fc is about equal for both methods. The rate of change of Fn is twice as fast for planes with a high cutting angle and low clearance angle. The conclusion is that the plane with a chipbreaker is technically more advanced then the plane with a high cutting angle. A hypothesis about how the two methods prevent tearout is proposed in this article too.

Introduction When smoothing wood with a handplane a common problem is tearout, the lifting of wood fibers from the surface when planing against the grain, because of the wedging action of the cutting blade. The woodworker will usually try to plane with the grain as much as possible but can’t always avoid it. Especially in curly wood, around knots and in cross grained species, the grain direction changes over short distances making it difficult or impossible to avoid planing against the grain. This has always been a problem for woodworkers but fashion dictated the use of more difficult types of wood in furniture in the 18th century, the mahogany period. Mahogany can be easy to plane, but it can also have very ornamental grain. Other luxury wood types from the period, like ebony and rosewood can be similarly difficult.

Fig. 1. Tearout when planing against the grain The first line of defense against tearout in the 17th and early 18th century was the handplane with a high cutting angle. Standard planes have a 45° cutting angle. In old German dictionaries (Hübner, 1714) and in the texts from Roubo (1769), planes with a cutting angle around 60° to 65° are described for planing hard and cross grained wood. Another tool was the toothing plane, a plane with a serrated cutting edge. This leaves a grooved surface which can be further smoothed with a scraper and helps to avoid tearout. In the second half of the 18th century the double iron plane is introduced. The double iron plane contains a normal cutting blade like all other planes, with a second blade similarly shaped and bolted upside down on top of the first one, with its edge positioned very close to the cutting edge. It is called the cover, capiron or the chipbreaker. Its function is to turn over the shaving just after it has been cut and thus reducing the possibility of the cut to propagate deeper into the wood. The cutting angle is usually between 45° and 50°. The earliest reference is an advertisement from the plane maker Samuel Caruthers in 1776: “Also, double-iron’d planes, of a late construction, far exceeding any tooth planes and uprights whatsoever, for cross grained or curled stuff” (Pollak, 1983). This short text explains precisely the position and purpose of the double iron plane at that time. It was a new invention, it was to replace planes with high cutting angle (uprights) and toothing planes and it was supposed to excel in tearout prone types of wood. This method of using the double iron plane is confirmed in later texts. “Enfin, le rabot ŕ deux fers […]celui de dessous doit avancer un peu plus ; & moins il excédera le second, moins il fera d'éclats;” (Salivet, 1796). “To prevent the iron from tearing the wood to cross grained stuff, a cover is used with a reversed basil (Nicholson, 1842). “The same effects [preventing tearout] are obtained in a much superior manner in the planes with double irons” (Holzapffel, 1856). The double iron plane became popular in the late 18th, early 19th century. Toothing planes were still being sold and used, especially for veneering. Steep angle planes became rare. There are several indications for this popularity like the accounts of writers of these days as mentioned above and the huge amount of double iron planes on the antique market today, while singe iron planes are quite rare. The famous Seaton tool chest from 1797 (Rees, 2012), which was almost completely preserved, contains 5 double iron bench planes versus only 2 with a single iron. Later in the 19th century the Stanley planes became a commercial success with the double iron design. Infill planes, made in England especially for the fine furniture makers, were usually configured with a 45° or 47˝° cutting angle and a chipbreaker too. At first glance it is strange that the double iron plane became so popular. The single iron plane is a simple design, it is quicker to setup, with a high cutting angle it works well to prevent tearout and they were considerably cheaper. In the tool catalog from the Arrowmammett Works (1858) the price of a double iron plane (70 cents) is the single iron plane (45 cents), plus the difference between a single iron and a double iron (17 cents), plus an extra 8 cents. An obvious advantage of the double iron plane is its ability to be adjusted to the task at hand. It can be used for benign wood and for difficult timbers by setting the chipbreaker closer to or further away from the edge. But most furniture making shops had dozens of planes and it wouldn’t have been a strange idea to have a plane specially setup for use on cross grained stuff. Another often mentioned advantage of the double iron plane is a smoother, less fuzzy wood surface, especially with softer types of wood. The question is, why did the more complex design became the more popular choice, not just for smoothing planes, but also jointers and jack planes? To investigate the possibility of mechanical advantages of the double iron plane, that are not directly obvious, this experiment has been designed. The idea is to measure the planing forces of handplanes with various settings and compare these to each other. Single iron plane setups with various cutting angles will be compared to double iron plane setups with chipbreaker settings that have the same effect on tearout. In recent years high angle planes became more popular again, for example bevel up planes with a high cutting angle and high angle frogs to convert normal iron bench planes, with the idea that they are easier to use. This experiment would not only help to explain the historical relevance of double iron planes, but it would also be useful for modern day users of handplanes to select the most efficient design. The second part of the experiment is investigating the difference in edge dulling rate between double iron and single iron planes.

Measuring plane forces and dulling of the cutting edge A lot of research has been done to determine the forces involved in wood cutting. But not all research is useful for handplanes. They often use rotating cutters, high speeds and low rake angles, all not very relevant for the handplane user. Two relevant studies are from Walker and Goodchild (1960) who measured the cutting forces on several wood species at cutting angles from 52.5° to 92.5° without chipbreakers, and Kato and Kawai (1989) investigated the effect of the chipbreaker, but only at a cutting angle of 40°. This makes it difficult to compare their results directly. From their research we can learn that the horizontal force in the cutting direction Fc, increases with increasing cutting angle and also increases with increasing chipbreaker effect (the chipbreaker effect is defined by the bevel angle of the chipbreaker γ, and the distance from the cutting edge D). The force on the edge in the vertical direction, the normal force Fn, is negative (cutting edge is pulled into the wood) for a cutting angle of 40° and a cutting depth of 0.05 mm and decreases, even to positive values, for higher cutting angles and stronger chipbreaker effect. Other important effects are the cutting depth and the grain angle of the wood. The cutting speed doesn’t have much effect, certainly not at hand planing speed.

Fig 2. Details and dimensions around the cutting edge. Dulling of the cutting edge in wood cutting has also been researched often. A review of many of these experiments is published by Klamecki (1978). Edge dulling is often measured with optical methods, looking at the edge, the roundness of the tip, the edge recession and the length of the wear bevels. These methods have one common disadvantage, they parameterize one aspect of the shape of the wear of the edge, but the real effect of a dull edge depends on its three dimensional shape. Some advanced work has been done with electron scanning microscopes looking from the side of the edge (Kato, 1989). Similar work with an optical microscope has been done by Elliott (2006) using a rabbet plane and watching the wear of the edge from the side. This was so important because it explains the wear behavior of a handplane blade, the formation of the convex wear bevel at the clearance side of the edge and its relevance to the feel of the plane in use. Another method to investigate edge dulling is to measure the forces on the plane Fc and Fn. Klamecki (1978) describes that the horizontal force Fc increases with the length of cut, and the normal force Fn changes more or less linearly with the increase of the wear bevel at the clearance side of the cutting edge. The experiments from Elliott (2006) show that this clearance wear bevel is important for a handplane. A comparison of single and double iron planes can only be made when it’s known how they perform on difficult wood in their ability to prevent tearout. Therefore an experiment was conducted to study this previously. A Stanley plane was used with backbevels to simulate various cutting angles and the effects on tearout prone pieces of wood was compared with various chipbreaker settings. The bevel angle of the chipbreaker γ was 44°. The results are in table 1. (Van der Heiden, 2014)

The experimental setup, part 1. Measuring force. A handplane in use is a very dynamic device. The user presses and pushes harder or softer on the plane, depending on the cut and the anisotropic nature of the wood. This makes it very hard to measure forces in a normal handplane during use. Each subsequent planing stroke yields different values. Early tests with a handplane featuring a force transducer under the handle confirmed this problem.

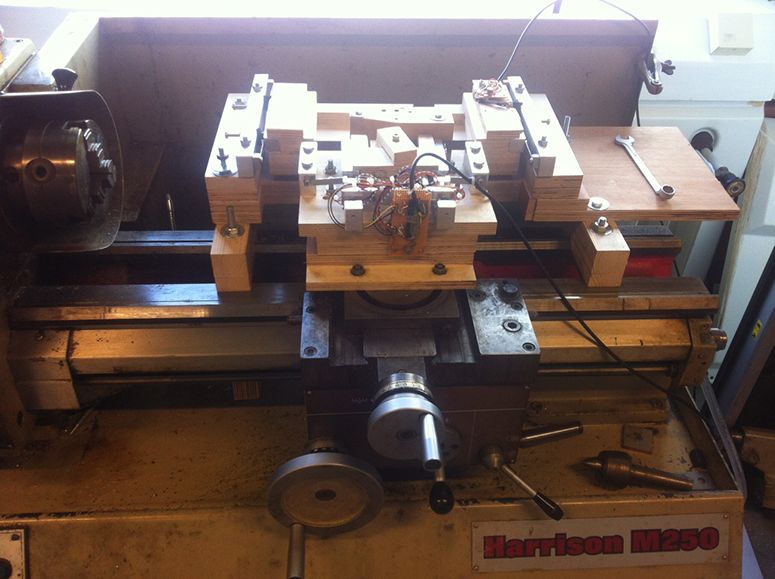

Fig 3. Experimental setup on the metal working lathe. To get useful data it was inevitable to build a planing machine mimicking the handplane as much as possible, but replacing the pushing hand with mechanical action. A metal working lathe with automatic feed has been adapted for this experiment. On the cross-slide a carrier is attached with the wood sample and force transducers to measure the normal force Fn. A bridge is made above the cross-slide in a stationary position with the cutting blade, also with a force transducer to measure the force in the cutting direction Fc. The advantage of this setup is the precise action of the automatic feed and the possibility to set the cutting depth accurately. A disadvantage is the missing plane sole and plane mouth, so the experiment is only an approximation of a real handplane.

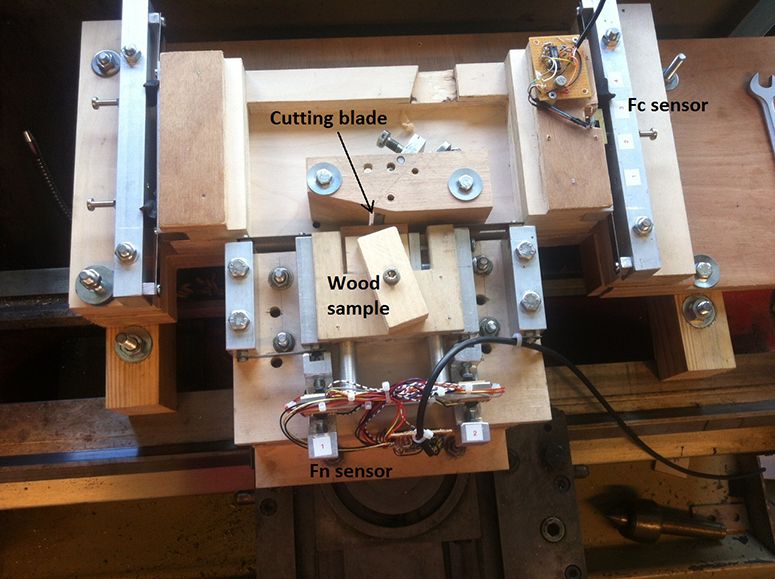

Fig 4. Overview of the measuring devices. The force transducers need a bit of movement to be able to measure, so the wood sample and the cutting blade are mounted with a little flexibility. This flexibility influences the cutting depth, despite the accurate setting. To compensate for this, four cuts are taken consecutively, removing 0.2 mm wood in total. The force transducers are sampled with a 40 Hz sample rate . This gives about 200 data points which are averaged to give a final value. The measurement is repeated three times for each setting. The type of wood used is beech, rift sawn and cutting is with the grain. The grain had an angle around 2° to 4° to the surface of the wood. In all experiments a cutting depth of 0.05 mm is used. Moisture content of the wood is 8 %. Cutting speed is 3 m / min. The cutting blade is a Hock high carbon steel plane blade. The grinding angle is 25° and the honing angle is 30°, honed on an 8000 grit Japanese waterstone. The face side of the blade is polished with a small backbevel around 0.5° on the same stone, to make sure that the sharpening burr is completely removed. The chipbreaker was prepared with a 40° bevel angle at first and later with a 50° bevel for some extra measurements. The blade can be mounted in the experimental setup at various angles. Cutting angles of 45°, 50°, 55° and 60° are tested without a chipbreaker. These are compared to chipbreaker setting at 0.3, 0.2 and 0.1 mm from the edge, according to table 1. The distance of the chipbreaker from the edge is measured with a microscope. The tests are randomly executed, to prevent unknown sequential effects having influence on the results. When using a handplane, the cutting of the wood is only one part of the force needed to push the plane. Another factor is the friction of the plane gliding over the wood. This is difficult to express in exact numbers because much of the friction depends on how hard the user presses down on the plane and this pressure varies a lot, within a planing stroke, but also from one stroke to the next. Some simple tests were conducted to see if this friction makes a relevant difference. The formula for the frictional force is Fr = Fn,tot * μk Fr is the frictional force, opposing the pushing force from the user. Fn,tot is the total normal force; the weight of the plane, the down force from the user and the normal force Fn from the cutting blade. µk is the kinetic frictional coefficient. This has been determined empirically to be 0.16 for wooden planes and slightly higher at 0.2 for steel planes with a waxed sole, on smooth wood. To get an idea how much down force is minimally necessary to cut a shaving, a Stanley #4 plane was pulled over a piece of pine with a string attached to the front knob. Weights were placed on top of the plane to see when a full width shaving at least half the length of the board was cut. This was done at 45° cutting angle, with and without chipbreaker and with a backbevel of 15° on the cutting blade to simulate a 60° plane. Results The results of the first part of the experiment are summarized in diagram 1.

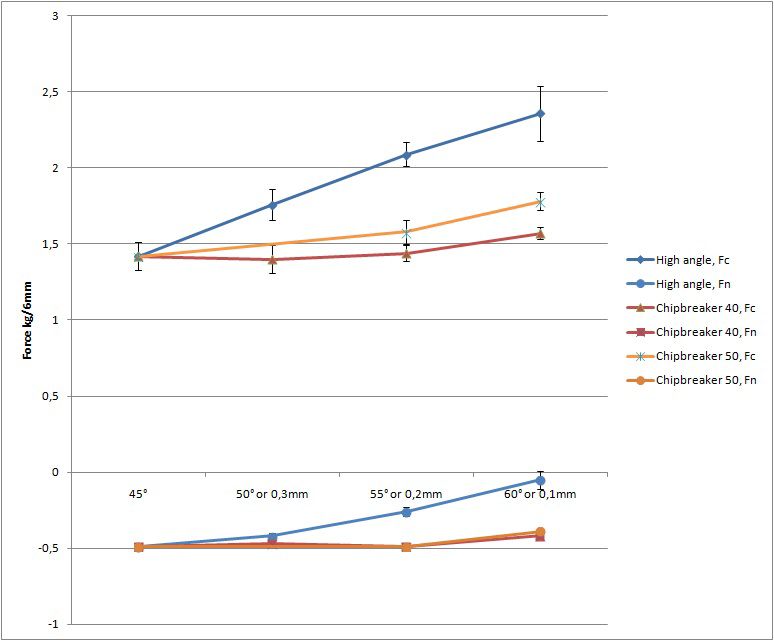

Diagram 1. Cutting forces Fn and Fc for various plane setups. There are three data lines for both forces Fn and Fc. The blue lines are the plane setups with varying cutting angles used without the chipbreaker. The orange lines are setups with a chipbreaker with a bevel angle of 50° at various distances from the edge. Finally the red lines are with a chipbreaker bevel angle of 40°. The horizontal axis displays the cutting angle, but also the distance of the chipbreaker from the cutting edge, in the position that was determined to be equivalent in the previous experiment (Van der Heiden, 2014). 60° cutting angle is the same as a chipbreaker distance of 0.1 mm. 55° is 0.2 mm. 50° is 0.3 mm (see table 1). For example, a single iron plane with a 60° cutting angle has a cutting force Fc of 2.35 kgf and a normal force Fn of -0.05 kgf. A double iron plane with similar capacity to reduce tearout has a chipbreaker bevel γ of 50°, set at 0.1 mm from the edge. Now the values are 1.8 kgf for Fc and -0.4 kgf for Fn. The vertical axis displays the measured forces Fc and Fn. The unit is kgf/6mm. This is the force in kg measured on a wood sample width of 6 mm. To get an idea about the frictional force, a plane was pulled over a piece of pine with a string attached to the front knob and a weight on top of the plane. The results are in table 2.

With these values it is possible to calculate the frictional force Fr. For example, a wooden smoothing plane of 0.8 kg and an extra down pressure from the user of 4 kg in addition to the minimal values from table 2. The width of the plane blade is 51 mm (2”). With the corners of the blade radiused this is about 7 times wider than the wood sample from the force measurements. Total normal force Fn,tot : Fn,tot = planeweight + additional weight + Fn * 7 Frictional force Fr: Fr = Fn,tot * μk Total horizontal force Fc,tot: Fc,tot = Fc + Fr Table 3 contains values for two examples.

In this example, the total force Fc is 29% higher for the 60° plane. Without the frictional forces this was 31%. The experimental setup, part 2. Measuring the dulling rate of the cutting edge. The same force measuring device is used to measure the increase of cutting forces when the edge gets dull. The wood sample in the measuring device is only 5 cm long, so it isn’t suitable for longer distances of wood planing. Therefore a simple planing beam is used separately. The plane blade is taken from the measuring device and set into a wooden handplane. Cutting depth is adjusted with a small hammer and checked by measuring the shaving thickness. The cutting depth is 0.05 mm. The planing beam has a fence, so the plane always cuts in the middle of the edge.

Fig 5. Planing beam with the wooden handplane and 50 meters worth of shavings. At 25 meter intervals the blade is put back into the experimental setup. Two shavings are taken to joint the edge of the wood sample. Then the forces are measured in the same way as described in part one. A few plane setups were tested, a 45° cutting angle without chipbreaker, a 45° cutting angle with the chipbreaker beveled at 50° and 0.1 mm from the edge and finally a 60° cutting angle simulated with a 15° backbevel on the blade which is bedded at 45°. All these setups have a clearance angle β of 15°. To study the effect of the clearance angle a second plane was prepared with a 60° bedding for the blade. With the same honing angle this results into a 30° clearance angle. A second method to determine the wear rate of the edge is possible with a microscope. Planing is done in a similar way as mentioned above and then the blade’s edge is positioned under a Dino-Lite USB microscope with 470x magnification. The bevel is first scratched with a carbide scribe just behind the edge to be able to measure the amount of edge recession. Using the microscopes measuring software the length of the wear bevel on the clearance side is also calculated. In this experiment two plane setups were tested. A 60° plane (actually the same 45° plane with 15° backbevel) and a 45° plane with the chipbreaker at 0.15 mm from the edge. Both were tested for 200 meters on the same type of beech used in the other experiments. The grain direction in the board varied from 5° against the grain at the start to 10° with the grain at the end of the board. Results The results of the measurements with the dulling blade are displayed in diagram 2.

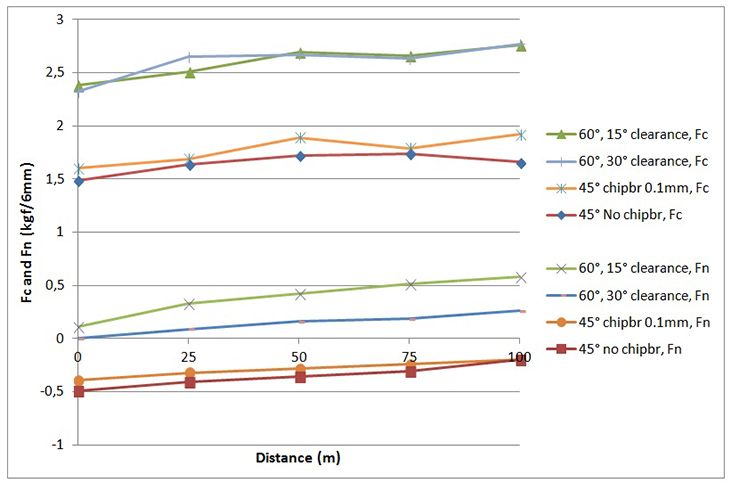

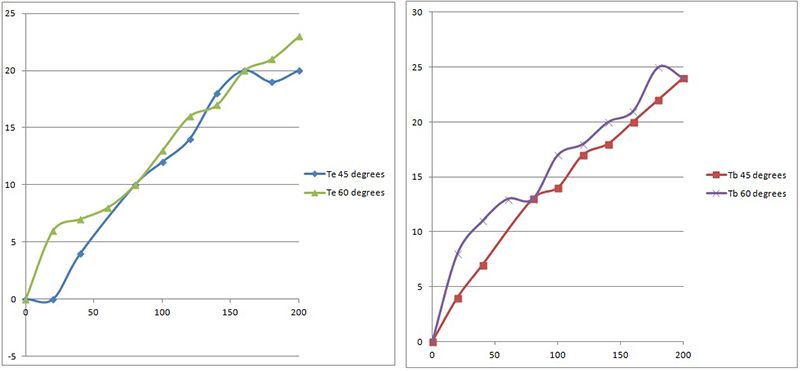

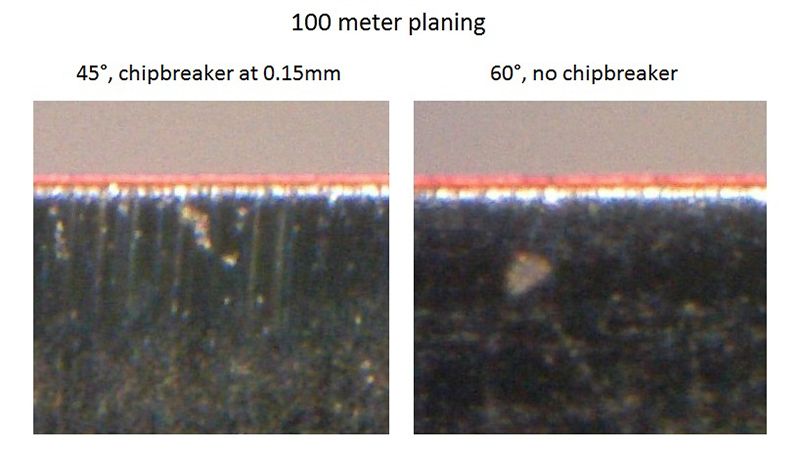

Diagram 2. Forces measured over distance planed. The values measured at 0m with a sharp blade are slightly different from the values in part 1. Between these two experiments the experimental measuring device has been upgraded with new sensors and a stiffer construction. Also new wood samples were used. Obvious details from diagram 2 are the higher values of Fc for the 60° planes, and the positive values of Fn also for the 60° planes which become more and more positive, while the values for the 45° planes remain negative. The slope of the lines is an indication for the dulling rate of the planes. This slope is more or less the same for all plane setups, with one exception. The line Fn for the 60° plane with 15° clearance angle is twice as steep as the other Fn lines. The microscope images allowed to measure the edge recession (Te) which is the measure of how much the blade is shortened. The length of the wear bevel on the clearance side of the blade (Tb) is also measured. The results are in diagram 3 and 4. Only the 60° plane with 15° clearance has been tested. Diagram 3. Te (µm) over distance planed (m). Diagram 4. Tb (µm) over distance planed (m). These diagrams show that there is not much difference between the two plane setups in regards to these two parameters. This is also visible in figure 6.

Fig. 6 Comparing the clearance wear bevel after 100 meters planing. 470x magnification.

Conclusions The force measuring device proved to be a successful method to quantify some mechanical aspects of handplanes. The force Fc was measured with more variability than the force Fn, but both gave interesting results. The absolute values depend on a lot of other variables too, like wood type, cutting depth and grain direction. Therefore only the values relative to each other are meaningful. The cutting force Fc in 60° and 55° planes is 31% higher than in a double iron plane with similar anti tearout properties. This is the force the user feels when pushing the plane forward. The normal force Fn doesn’t change much in the double iron planes and remains negative, pulling the edge into the wood. In the high angle planes, Fn changes more rapidly and reaches zero around a 60° cutting angle requiring the user to force the plane into the wood surface rather than being pulled into the wood surface by the cutting edge. The calculations of the frictional force are based on many assumptions. But still they show that the influence of the friction is small and doesn’t affect the above conclusions. The total normal force is quite similar for both plane setups and the small value of µk makes the influence of friction even smaller. Tearout happens when planing against the grain, when the wedging action of the blade overcomes the bonding strength of the wood fibers, the force Fn is a measure of this wedge. In high angle planes this effect is reduced because the wedging action is reduced. With a shaving thickness of 0.05 mm and a grain angle of 4 degrees like in this experiment, the edge doesn’t act like a wedge anymore from 60° upwards. Double iron planes don’t have this reduction of Fn, but they are equally capable of reducing tearout. The name of the chipbreaker suggests that it breaks the shaving before it can pull the wood fibers out of the wood, but a broken shaving wouldn’t press down on the edge either, and Fn would be reduced just like in a high angle plane. The shaving is a leaf spring which presses down on the face of the blade and the chipbreaker. This forms a resistance to the flow of the shaving, which increases when the radius of the shaving curl is tightened because of a steeper chipbreaker bevel or when the chipbreaker is set closer to the cutting edge. This resistance causes a counterforce which is transmitted through the shaving to the point where it is still attached to the wood. This counterforce supports that attachment and prevents tearout. This hypothesis is supported by the wear patterns in Kato’s article (1989). Further research is necessary to prove or dismiss this hypothesis. The experiments with a dulling blade with force measurements and microscope images were interesting too. Fc increases at a similar rate for both high angle planes and double iron planes. Likewise there was not much difference between the length of the clearance wear bevels or the amount of edge recession. The only parameter which showed obvious different behavior is the normal force Fn. This increases twice as fast in the 60° plane with 15° clearance angle compared to the other plane setups over a distance of 100 meters. The handplane user needs to push this high angle plane down harder and this leads to more friction when the edge dulls. The increase of Fn in the 60° plane with 30° clearance was close to half of the increase in the 60° plane with 15° clearance. This leads to the conclusion that a high cutting angle and low clearance angle is not an ideal combination. The increase in Fn when the edge gets dull is often associated with the length of the clearance wear bevel. This doesn’t seem to be the case here, which leads to the conclusion that this microscope method isn’t useful to study differences in wear behavior between different plane setups. The double iron plane has mechanical advantages over the high angle plane. It is easier to push and has a stronger negative normal force which feels like it cuts better with less down force. This advantage remains when the edge gets dull, while high angle planes with a low clearance angle perform worse. The true motives of the woodworkers of the 18th century will probably remain a mystery forever, but this experiment demonstrates that the double iron plane is a technological step forward. For the modern woodworker that is useful to know too. . Literature Arrowmammett Works (1858), Catalogue and Invoice Pricelist of Bench Planes and Moulding Planes. Middletown: Arrowmammett Works. Elliott, S. (2006). Wear profiles. From http://bladetest.infillplane.com/html/wear_profiles.html. Holtzapffel, C. (1856). Turning and mechanical manipulation Vol II. London: Holtzapffel & co. Hübner, J. (1714). Curieuses und reales Natur-, Kunst-, Berg-, Gewerck- und Handlungs-Lexicon. Hamburg: Joh. Fried. Gleditsch. Kato, C. and Kawai, Y. (1989). Wear of knife used in hand plane III: the influence of the capiron. The Japan Wood Research Society Vol. 35, no. 10, p. 886-895. Klamecki, B.E. (1979). A review of wood cutting tool wear literature. Holz als Roh- und Werkstoff 37 265-276. Nicholson, P. (1842). The Mechanic’s companion. Philadelphia: John Locken. Pollak, E and Pollak, M. (1983). A guide to the makers of American wooden planes. Apple Valley: Astragal Press. Roubo, A. (1769). L’Art du Menuisier. Paris: Académie des Sciences. Salivet, L.G.I. (1796). Atlas ou manuel de Tourneur. Paris. Rees, J. et. al. (2012), The toolchest of Benjamin Seaton 2nd edition. Taunton: TATHS. Van der Heiden, C.W. (2014). Surface quality for different wood plane settings. From http://planetuning.infillplane.com/html/cap_iron_study_by_kees_van_der.html. Walker, K.J.S. and Goodchild, R. (1960). Experiments in rectilinear cutting (Part 1). Forest Products Research Special report No. 14.

The original of this study is available in pdf format here.

|

|

[Home] [Summary of Results] [Testing Procedure] [Chipbreaking] [Chipbreaker Tests] [Chipbreaker Study] [A Controlled Test] [Review of Cap Iron Study] [Cap Iron Study by Kees van der Heiden] [Mechanics of Chipbreakers] [Cutting Angles] [Shaving Formation] [Tuning Infill Planes] [Links & References] [Contact] [Site Map] |